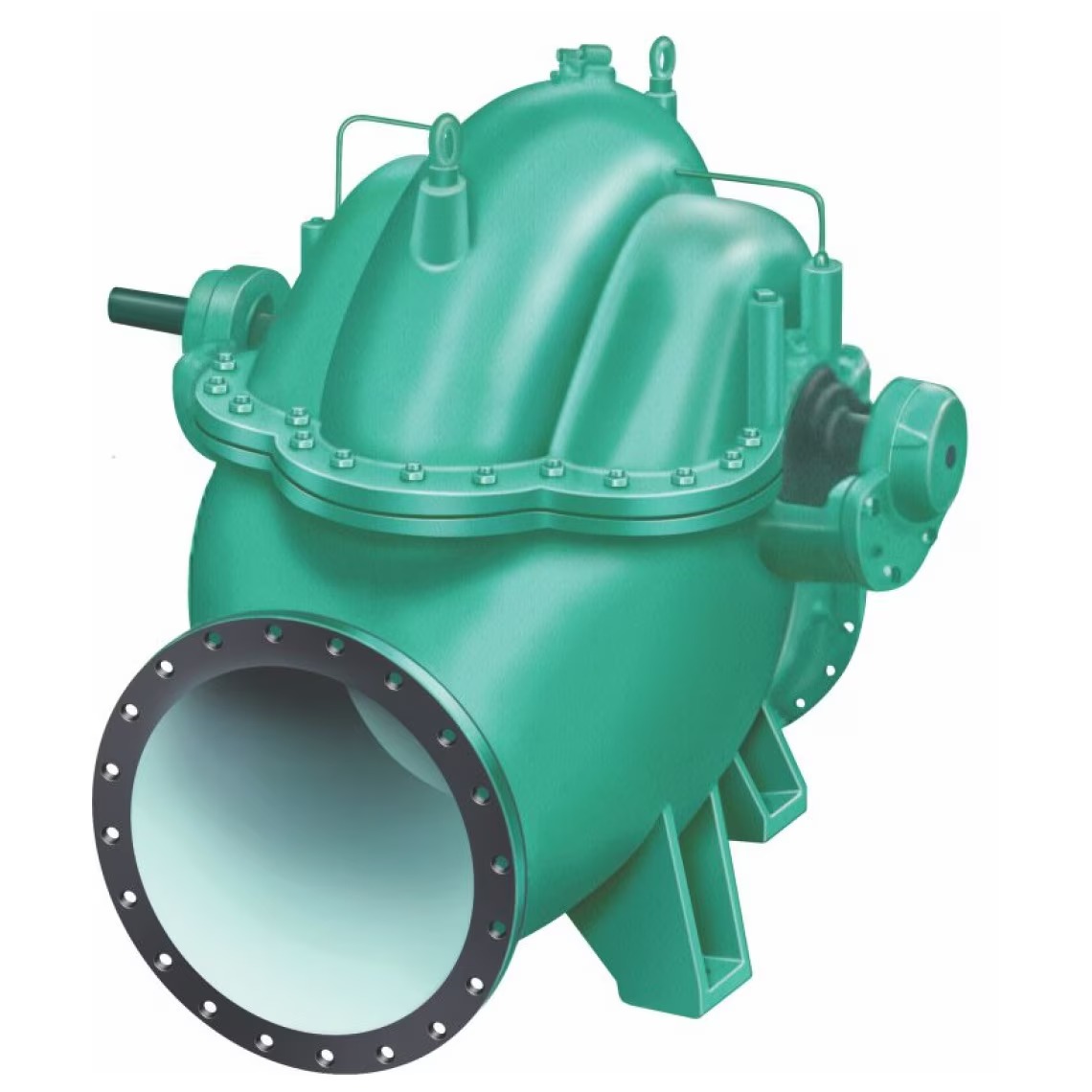

Description

The End Suction Pump in accordance with ISO 2858 (commonly referred to as MISO/PISO) is a centrifugal pump designed to meet the ISO 2858 standard for dimensional and performance requirements. These pumps are widely used in various industries, including water treatment, chemical processing, and general manufacturing, due to their reliability, efficiency, and ease of maintenance.

Key Features and Specifications

- Standardization: The ISO 2858 standard ensures that these pumps have standardized dimensions, including suction and discharge nozzle dimensions, mounting interfaces, and shaft size, making them easily interchangeable and compatible with other ISO-standard components. This facilitates global use and simplifies the process of replacements or upgrades.

- Design and Construction:

- Single-Stage, End Suction: These are typically single-stage, with an axial suction inlet and a radial discharge outlet positioned perpendicular to the shaft.

- Back Pull-Out Design: The back pull-out feature allows for easy maintenance and inspection without needing to dismantle the pump casing or disturb the pipe connections. This minimizes downtime.

- Volute Casing: Designed to reduce radial thrust and enhance hydraulic efficiency, the volute casing provides smooth flow characteristics.

- Impeller Options: These pumps typically feature closed impellers for efficient fluid handling and can be modified for open or semi-open impellers based on the application requirements.

- Materials: Available in a range of materials, including cast iron, stainless steel, and specialty alloys, to handle different types of fluids and corrosive environments.

- Operational Efficiency:

- High Hydraulic Efficiency: The design is optimized for high efficiency, ensuring energy savings and cost-effectiveness.

- Low NPSHr: These pumps are designed to have a low Net Positive Suction Head required (NPSHr), minimizing cavitation risks and allowing for stable operation under challenging suction conditions.

- Flow Rate and Head: Typically suitable for medium to high flow rates, with heads up to 160 meters and flow rates that vary according to pump size and impeller trim.

- Performance Standards:

- ISO 5199 Compliance: In addition to ISO 2858, many MISO/PISO end suction pumps also comply with ISO 5199 standards for mechanical reliability, making them highly suitable for heavy-duty industrial applications.

- Variable Speed Options: These pumps can often be coupled with variable frequency drives (VFDs) to optimize energy usage based on real-time demand.

- Applications:

- Water and Wastewater Treatment: Used in processes involving clean water as well as mildly contaminated fluids.

- Industrial Processing: Ideal for handling various chemicals, oils, and light slurries in sectors such as food processing, pharmaceuticals, and petrochemicals.

- Agriculture and Irrigation: Commonly deployed in irrigation systems and drainage applications for their durability and efficient operation.

- HVAC Systems: Used in heating, ventilation, and air conditioning systems for efficient fluid circulation.

- Advantages:

- Ease of Maintenance: The standardized dimensions and back pull-out design allow for quick maintenance and reduced downtime.

- Energy-Efficient Operation: Engineered to operate at high efficiency, reducing operational costs and energy consumption.

- Interchangeability: Due to ISO standardization, parts are readily available and interchangeable, making replacements more convenient and cost-effective.

Common Variants

- MISO (Metric ISO): Typically designed with metric measurements, aligning with international specifications.

- PISO (Pumps ISO): Can refer to configurations optimized for specific pump manufacturers, focusing on slight design modifications while adhering to ISO standards.