Description

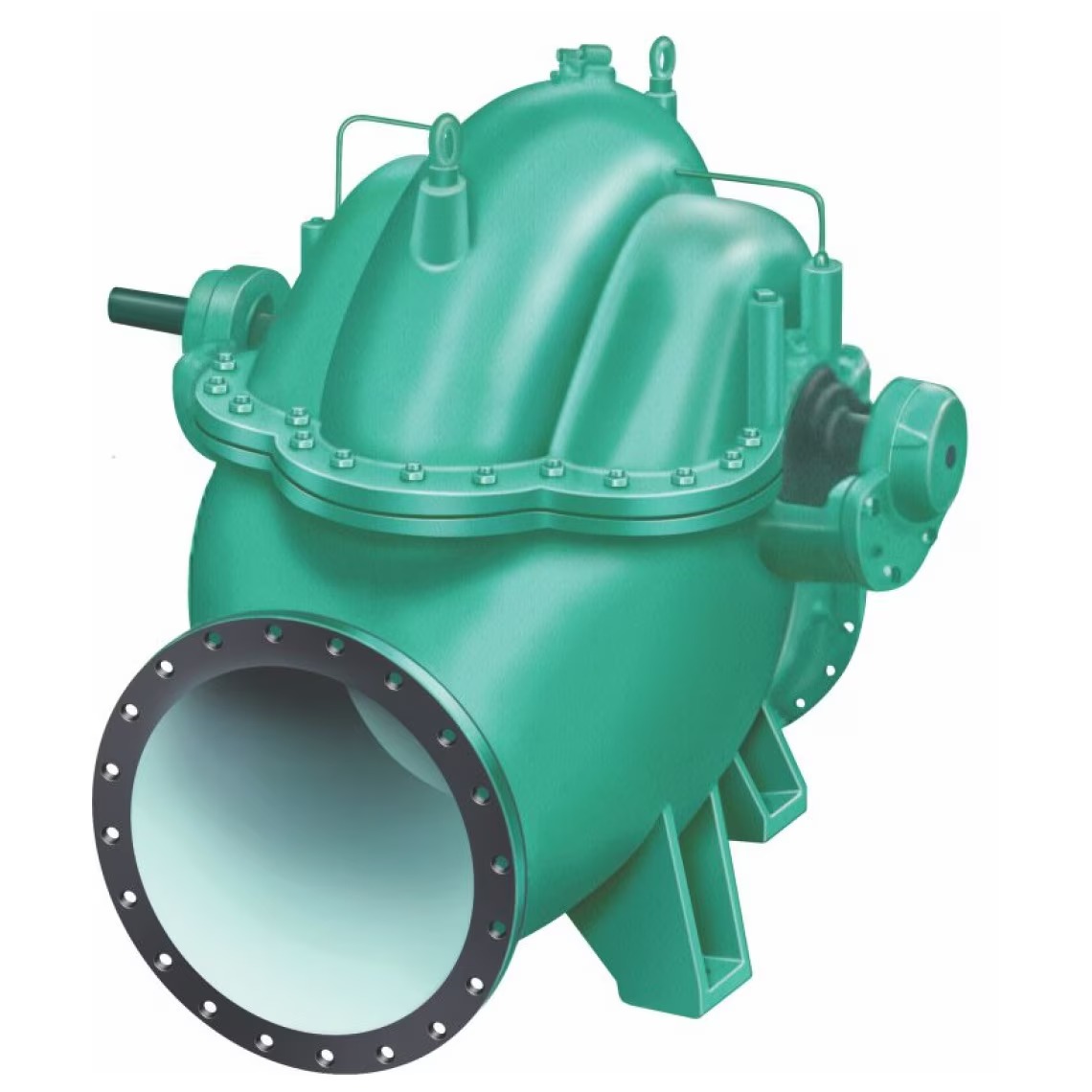

An End Suction Pump is a widely-used centrifugal pump known for its versatility, efficiency, and relatively simple construction. It features an impeller attached to the end of a horizontal shaft, drawing fluid into the pump axially and discharging it radially, making it ideal for various applications across different industries.

Key Features and Engineering Specifications:

- Design: End suction pumps are typically single-stage centrifugal pumps, with an impeller that is supported at one end. The design enables smooth fluid flow and optimized efficiency.

- Construction Materials: They are engineered in a variety of materials, such as cast iron, stainless steel, and bronze, allowing customization based on the type of fluid being pumped, environmental conditions, and operational needs.

- Flow and Head Capacities: These pumps can handle a wide range of flow rates and head pressures, making them adaptable to various applications with both high and low pressure and flow requirements.

- Port Configurations: Inlet and outlet ports are positioned for convenient connection, often arranged so that the discharge is perpendicular to the inlet, enabling straightforward installation and maintenance.

Engineering/Specialized Applications:

End suction pumps can be customized for specialized applications, ensuring optimal performance and longevity. Some engineering specialties and customizations include:

- High-Temperature Applications: Special seals and materials can be used to manage fluids at elevated temperatures, suitable for industries like chemical processing and HVAC.

- Corrosion and Abrasion Resistance: Custom material options and coatings, such as stainless steel or ceramic lining, are available for pumping aggressive fluids or handling abrasive particles, useful in mining, wastewater, and other industrial applications.

- Energy Efficiency Optimization: High-efficiency motors, variable speed drives (VSDs), and specially designed impellers reduce energy consumption and improve the pump’s operational efficiency, aligning with sustainability goals.

- Noise Reduction and Vibration Control: Specialized mounts, couplings, and balancing techniques ensure smoother, quieter operation, which is crucial for environments like residential or commercial buildings.

- Enhanced Seal Options: Advanced mechanical seal designs or magnetically driven options provide increased reliability and leak protection, which is vital in applications handling hazardous or sensitive fluids.

Advantages of Engineered/Special End Suction Pumps:

- Customization for Application: They can be tailored to specific operational requirements, including duty point optimization, materials, and special coatings.

- Maintenance Friendly: Easy access to the pump’s internal components allows for quicker, cost-effective maintenance.

- Space-Efficient: The compact footprint allows for installation in tighter spaces, making them ideal for retrofitting or locations with space constraints.

- Cost-Effective Solution: With fewer parts and simpler construction, they often present a cost-effective option compared to other centrifugal pumps, especially in lower flow applications.

Common Applications:

End suction pumps are found across diverse applications, including:

- Agriculture: Irrigation systems, water transfer, and livestock water systems.

- HVAC Systems: Circulating water in heating and cooling systems.

- Municipal and Industrial Water Systems: Pressure boosting, water treatment, and distribution networks.

- Commercial Buildings: Water supply, firefighting systems, and drainage systems.

- Process Industry: Chemical transfer, cooling tower water, and general water circulation in industrial processes.