Description

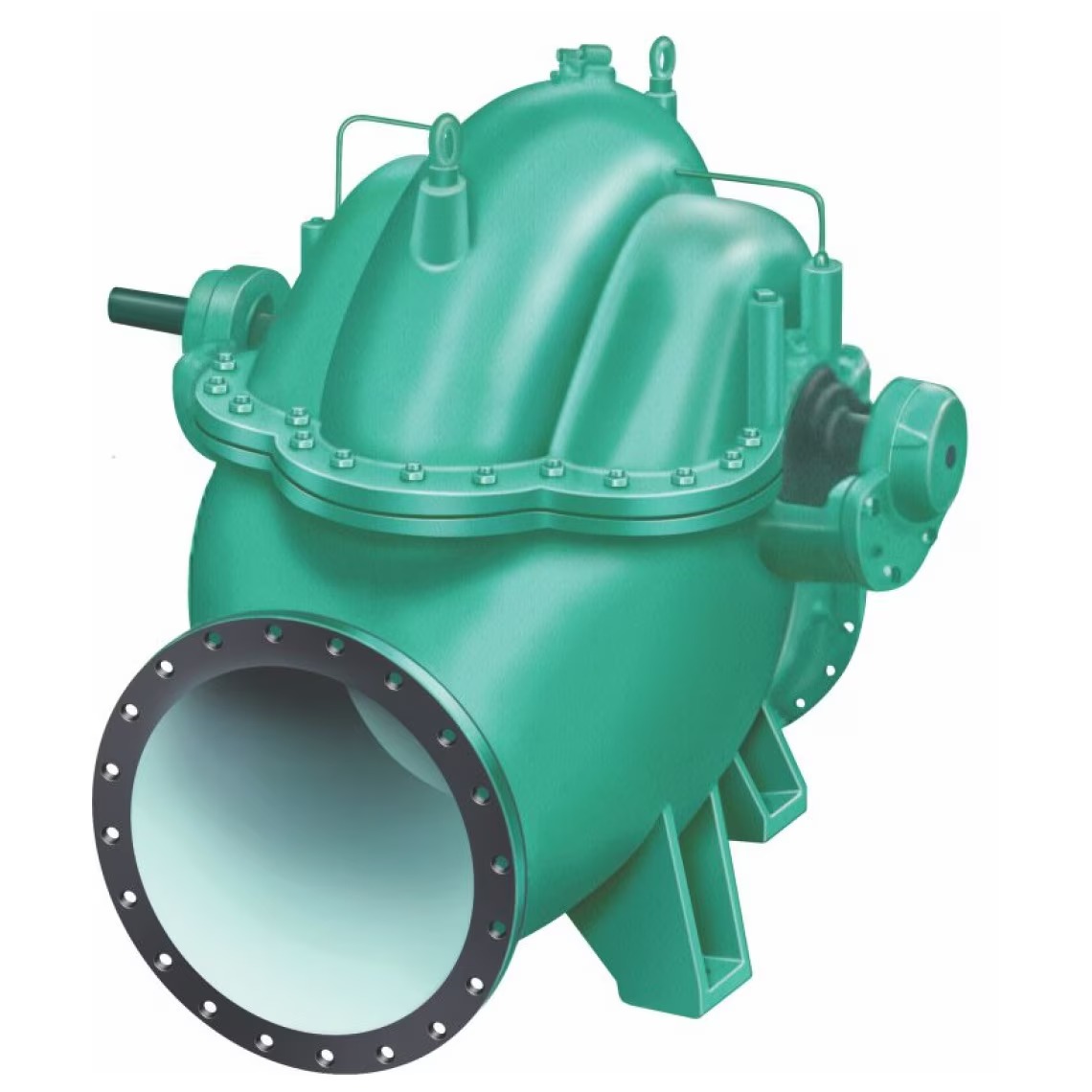

An Engineered Horizontal Split Case Pump (HSC) is a type of centrifugal pump widely used for applications that require high efficiency, reliability, and durability, especially in large flow and high-head environments. The unique design of these pumps makes them suitable for various applications, including water supply, irrigation, HVAC systems, industrial processes, and fire protection systems. Here’s a detailed breakdown of their characteristics and advantages:

Key Features

- Horizontal Split Case Design:

- The pump casing is horizontally split, meaning the casing can be opened horizontally along the shaft centerline, which allows easy access to internal components for maintenance and inspection without disconnecting the pump from the piping.

- This design reduces downtime, making it a preferred option for continuous operation environments.

- High Efficiency:

- HSC pumps are known for their high efficiency, driven by advanced hydraulic designs that minimize energy losses during operation.

- These pumps are often optimized to provide maximum hydraulic efficiency, which helps reduce operating costs in energy-intensive applications.

- Robust Construction:

- Typically constructed with durable materials, such as cast iron, bronze, or stainless steel, which enhances longevity, even under harsh operating conditions.

- They are designed to handle large flows and high pressures, making them suitable for demanding applications.

- Double Suction Impeller:

- A key feature of many HSC pumps is the double-suction impeller, which allows fluid to enter from both sides, balancing axial thrust and enhancing hydraulic efficiency.

- The double-suction design reduces cavitation risks, ensuring reliable performance in varying flow conditions.

- Precision Bearings and Shaft Alignment:

- The bearings and shaft alignment in engineered HSC pumps are meticulously designed to minimize wear and enhance the operational lifespan of the pump.

- High-quality bearings support continuous operation with low vibration and noise, contributing to a more stable, low-maintenance system.

Advantages

- Ease of Maintenance: With the horizontally split case, maintenance and inspection tasks are streamlined, minimizing labor and downtime, which is essential for critical applications like municipal water supply and industrial processes.

- High Capacity and Versatility: HSC pumps can handle large volumes of water, making them ideal for municipal water services, irrigation, and industrial applications where large-scale fluid movement is required.

- Energy Savings: The high hydraulic efficiency and balanced design allow for significant energy savings over other types of pumps, lowering the total cost of ownership.

- Longer Operational Life: Their sturdy construction, precision alignment, and low wear characteristics contribute to a longer life cycle compared to other pump types, making them cost-effective over the long term.

Common Applications

Engineered horizontal split case pumps are suitable for:

- Water Supply Systems: Municipal water distribution and treatment plants.

- Irrigation and Agriculture: Large-scale irrigation projects that require high flow rates.

- Industrial Processing: Industries such as oil and gas, power generation, and chemical processing that need reliable and efficient fluid handling.

- HVAC Systems: Cooling and heating applications in large buildings.

- Fire Protection Systems: Critical infrastructure requiring high-pressure water delivery.

Customization and Engineering Flexibility

Engineered HSC pumps can be customized to meet specific needs, including:

- Material Selection: Options for corrosive or abrasive applications, such as specialized metals or coatings.

- Performance Tuning: Pump configuration and impeller adjustments to match particular flow and pressure requirements.

- Seal and Bearing Customization: Enhanced seals and bearings to accommodate specific operating conditions, like high-temperature or high-pressure environments.