Description

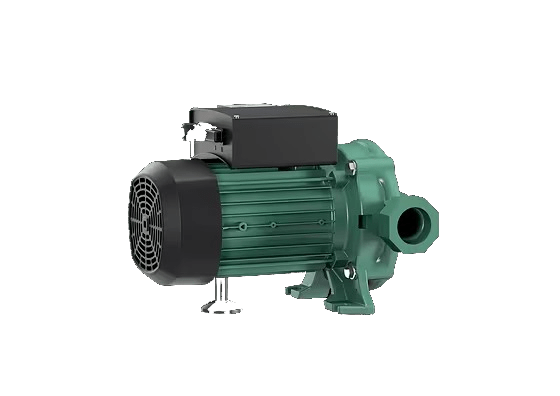

The Monoblock Pumpset 3 Phase – MPM is a type of centrifugal pump designed for a wide range of applications, particularly in water supply, irrigation, and industrial use. Manufactured by various pump companies (such as Wilo, Kirloskar, Crompton, or similar), this monoblock pumpset is typically powered by a 3-phase electric motor and is designed to offer high efficiency, durability, and reliability in demanding environments.

Key Features of the Monoblock Pumpset 3 Phase – MPM:

- Design & Construction:

- Monoblock Design: The term monoblock refers to the pump and motor being mounted as a single unit, making the setup compact and easy to install. The pump casing and motor are integrated into a single structure, which simplifies the assembly process and reduces the likelihood of misalignment.

- Centrifugal Action: These pumps use centrifugal force to move water or fluids, making them ideal for a variety of applications where high-flow rates and consistent water pressure are needed.

- Corrosion-Resistant Materials: The pump components (including the casing, impeller, and shaft) are typically made from cast iron, stainless steel, or other corrosion-resistant materials to ensure durability and long service life, even in harsh conditions.

- 3-Phase Motor: The 3-phase motor provides high power output and ensures more efficient energy consumption compared to single-phase motors, making it suitable for large-scale operations. It is also more reliable and requires less maintenance.

- Applications:

- Water Supply Systems: Suitable for applications in residential, commercial, and industrial water supply systems, the Monoblock Pumpset can be used to transport water to different areas or to boost water pressure in municipal water supply systems.

- Irrigation: The pump is often used in agriculture and irrigation systems, where large volumes of water need to be moved efficiently and effectively, particularly for drip irrigation or sprinkler systems.

- Booster Systems: The MPM pump is ideal for pressure boosting in high-rise buildings, hotels, and complexes, where water pressure is needed at higher altitudes or for consistent water supply across multiple floors.

- Industrial Applications: It can be used in various industrial processes requiring the transfer of water or other fluids, such as in cooling systems, liquid transfer, and hydraulic systems.

- Swimming Pools and Water Treatment: The pump is also useful in water treatment plants and swimming pool filtration systems, where consistent flow and pressure are crucial.

- Energy Efficiency:

- The 3-phase motor offers higher energy efficiency, providing more power with less energy consumption than single-phase motors.

- These pumps are designed for continuous operation, making them ideal for systems that require constant operation, such as irrigation systems, industrial applications, or water treatment processes.

- Many models are designed to meet or exceed modern energy efficiency standards, which helps reduce operational costs over the pump’s lifetime.

- Durability & Maintenance:

- High-quality construction ensures that the Monoblock Pumpset 3 Phase – MPM has a long service life, even under continuous use in harsh environments.

- The bearing system is typically designed to handle high radial loads, ensuring smooth operation and reducing wear over time.

- Low maintenance requirements: The monoblock design simplifies the maintenance process, and the pump is usually designed for easy disassembly, making it more convenient for repairs and part replacements.

- Sealing System: The pumps often feature mechanical seals to prevent leakage and ensure safe operation.

- Performance & Efficiency:

- High Flow Rates: The Monoblock Pumpset 3 Phase is designed to handle high flow rates, making it ideal for applications that require the transfer of large volumes of water or other fluids.

- Head Pressure: These pumps can generate considerable head pressure, which is required in applications such as water lifting, pressure boosting, or irrigation where water needs to be pumped to greater heights or through long pipelines.

- The impeller design is optimized for maximum efficiency, reducing the energy required to achieve the desired flow rates.

- Safety Features:

- Thermal Overload Protection: The pump motor often includes thermal overload protection, which automatically shuts off the motor in case of overheating to prevent damage.

- Dry-run Protection: In some configurations, dry-run protection may be included to prevent the pump from running without fluid, which can cause severe damage to the pump components.

- Self-priming: Some models are designed to be self-priming, which makes them more reliable and easier to operate in systems where the pump may need to be restarted after running dry or after maintenance.

- Noise & Vibration Control:

- Balanced motor and impeller: The motor and impeller are often well-balanced to reduce vibration, ensuring quieter operation and minimizing wear.

- The pump system is engineered to minimize noise pollution during operation, which is beneficial for residential or commercial installations where noise control is essential.

Advantages of the Monoblock Pumpset 3 Phase – MPM:

- High efficiency and reliability due to the use of a 3-phase motor.

- Durable design, made to withstand harsh environments and offer long-term service.

- Low maintenance and easy to service, thanks to its monoblock construction.

- High-performance in applications requiring high flow and pressure.

- Energy-efficient operation, which reduces operational costs.

- Versatility in a wide range of applications, including irrigation, water supply, and industrial use.

- Safety features, including overload protection and dry-run prevention, enhance operational safety.

Applications of the Monoblock Pumpset 3 Phase – MPM:

- Agriculture/Irrigation: Perfect for agricultural irrigation systems, including drip irrigation, sprinkler systems, and water distribution for crops.

- Water Supply: Ideal for municipal water supply systems or booster systems in residential and commercial buildings.

- Fire Protection: Used in fire-fighting applications where high pressure is required for water distribution during emergencies.

- Industrial Use: Efficient for cooling systems, fluid transfer, and other industrial fluid movement requirements.

- Swimming Pool Filtration: Used to pump and circulate water through swimming pool filtration systems.

- Water Treatment: Employed in water treatment plants for circulating water and ensuring proper filtration and flow.

Conclusion:

The Monoblock Pumpset 3 Phase – MPM is a versatile, high-performance, and energy-efficient pump system designed for applications requiring high flow rates and reliable pressure. It is ideal for irrigation, water supply, and industrial uses. The 3-phase motor ensures superior power and efficiency, making it a popular choice for commercial and residential systems. With its durable construction, low maintenance needs, and reliable operation, the MPM Monoblock Pumpset is an excellent solution for ensuring smooth, continuous water or fluid circulation in a variety of applications.