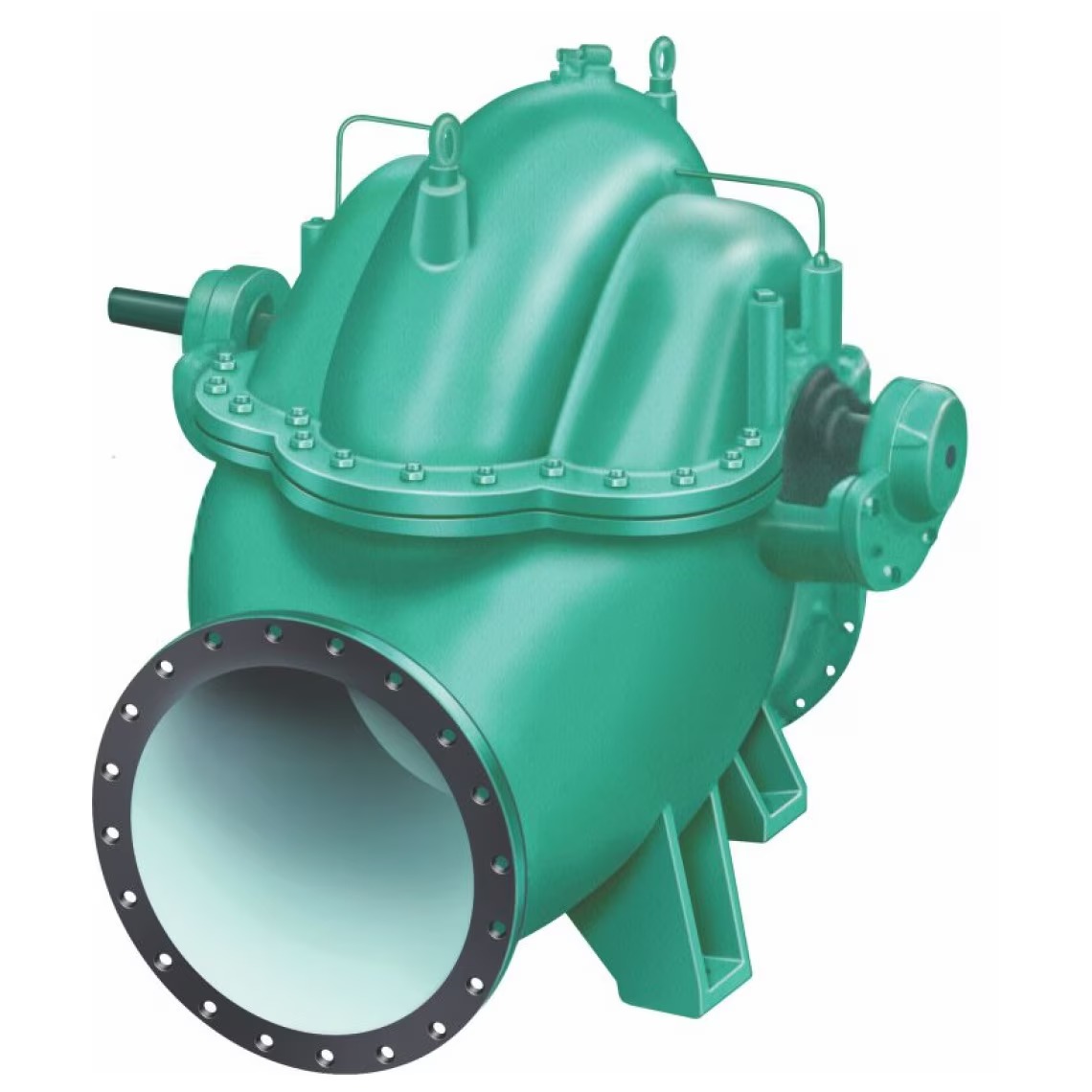

Description

A Multistage Ring Section Pump is a type of centrifugal pump designed for applications requiring high pressure and efficient handling of fluids across long distances or elevation changes. Here’s an in-depth look at its construction, functionality, applications, and advantages:

1. Design and Construction

- Multistage Configuration: Multistage ring section pumps have multiple impellers arranged in a series, where each impeller increases the pressure progressively. This multi-stage setup allows for significant pressure increases while maintaining a relatively compact footprint.

- Ring Section Casing: The pump features a modular “ring section” or segmented casing design, where each stage (or impeller section) is encased in a separate ring-like housing. These rings are clamped together, forming a stack of identical sections that allows for easy assembly, disassembly, and maintenance.

- Balanced Rotors and Axial Thrust Management: The design of these pumps often incorporates balancing mechanisms like balance discs or pistons to counteract axial thrust, enhancing durability and operational stability.

- Sealing and Bearings: They generally use mechanical seals or stuffing boxes to prevent fluid leakage. Bearings are used to support the rotating shaft and ensure smooth operation under high-pressure conditions.

2. Working Principle

- The fluid enters the pump through the suction side and flows into the first impeller, which increases the pressure and transfers the fluid to the next stage. This sequence continues through each impeller stage, building up pressure progressively.

- The pumped fluid exits the final stage at a significantly higher pressure than it entered, achieving the desired output for high-pressure applications. The axial thrust generated by multiple stages is managed by balance mechanisms to reduce wear and enhance efficiency.

3. Applications

Multistage ring section pumps are widely used in scenarios that demand high-pressure output and consistent flow. Some common applications include:

- Municipal Water Supply: Ideal for urban water distribution systems that require high-pressure capabilities to supply water across large areas or to elevated regions.

- Boiler Feed in Industrial Plants: These pumps are often employed in thermal power plants to feed water to boilers at high pressure.

- Irrigation Systems: Efficient for agricultural irrigation systems, especially where water needs to be transported over long distances or varied terrains.

- Mining and Dewatering: Effective in mining operations where high-pressure water needs to be pumped for mineral processing or dewatering tasks.

- Desalination Plants: Used in high-pressure reverse osmosis applications to push seawater through membranes to produce potable water.

- Firefighting Systems: Incorporated in firefighting pumps, where high-pressure and reliable water supply is essential for emergencies.

4. Advantages

- High Efficiency and Pressure Handling: With multiple impellers, these pumps can achieve high pressure without needing a larger or bulkier pump, maintaining efficiency even under demanding conditions.

- Modular Design for Easy Maintenance: The ring-section structure allows for simple disassembly and reassembly, making maintenance and repairs more manageable.

- Durable and Reliable: Made from robust materials, often cast iron or stainless steel, these pumps are designed to withstand high pressures and various environmental conditions.

- Compact Size for High Pressure: Compared to single-stage pumps that would need to be larger to achieve similar pressures, multistage ring section pumps are more compact.

- Flexible and Customizable: Due to the modular nature, the number of stages can be customized to achieve specific pressure and flow requirements, making them adaptable to various applications.

5. Limitations

- Higher Initial Cost: Multistage ring section pumps are generally more expensive than simpler single-stage pumps due to their complexity.

- Maintenance Complexity: While the modular design aids in repairs, the multiple stages and seals mean more components that may need regular maintenance.

- Axial Thrust Considerations: High axial thrust is generated in multistage configurations, so proper balancing and precision in design are critical to avoid wear and operational issues.