Description

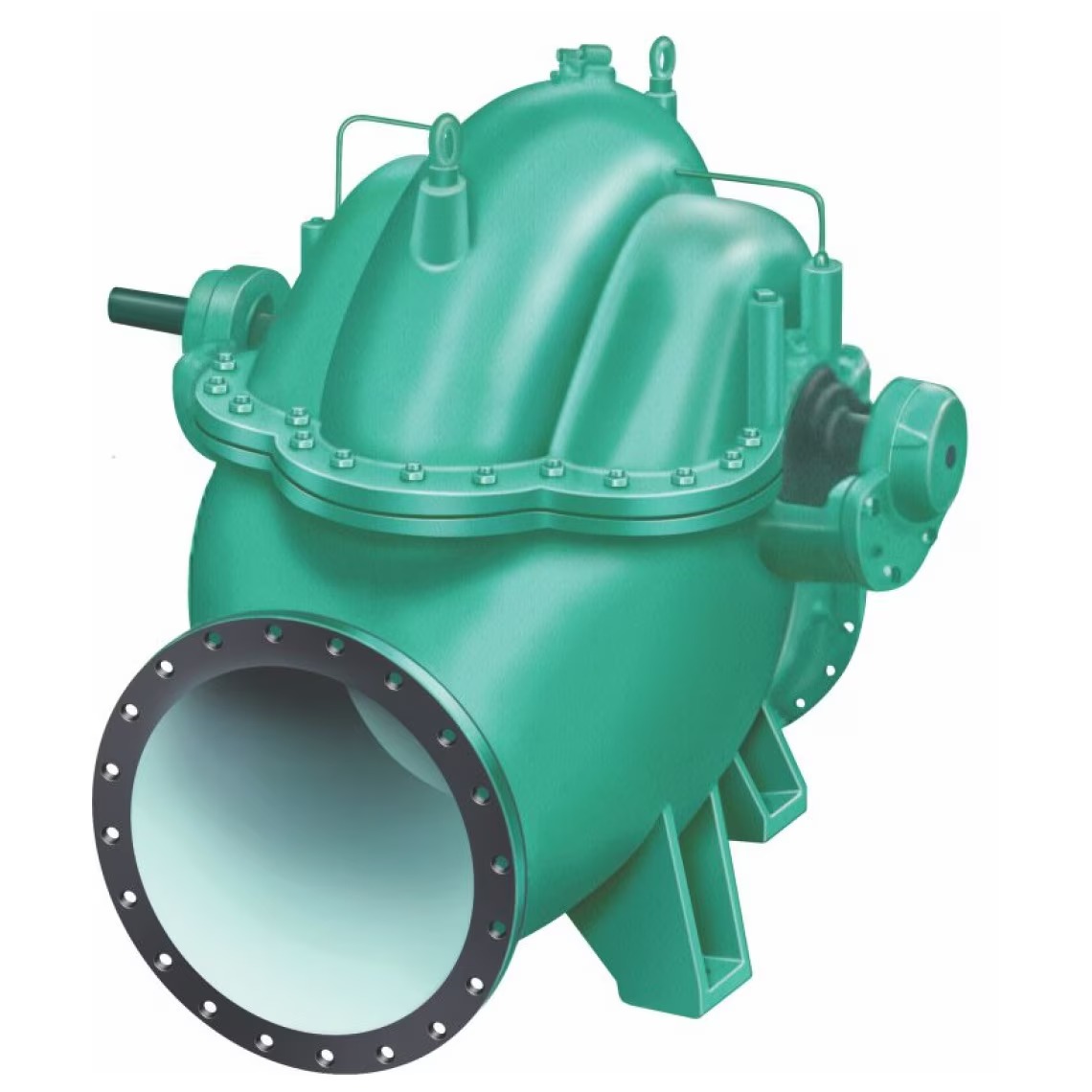

A standard horizontal split case pump is a widely used type of centrifugal pump designed for high efficiency, high flow rates, and reliable performance in a variety of applications. This pump type is named for its casing design, which splits horizontally, allowing for easy access to internal components for maintenance and servicing without the need to disconnect the piping. Here’s a detailed description:

Key Features and Design

- Horizontal Split Casing: The pump casing is split horizontally along the shaft centerline, making it easy to access the rotor, bearings, and other internal components. This design reduces downtime and maintenance costs, as the pump can be serviced without disturbing pipe connections.

- Dual Suction Impeller: These pumps typically feature a double-suction impeller, which draws water from both sides of the impeller. This design balances the axial forces within the pump, providing smoother operation, higher efficiency, and a longer lifespan for the pump.

- Heavy-duty Bearings and Shaft: Horizontal split case pumps are often equipped with robust bearings and a strong shaft to handle high pressures and heavy loads. This design enhances durability and reliability, even under rigorous conditions.

- High Efficiency: Due to their dual suction design and well-engineered internal hydraulics, horizontal split case pumps offer excellent efficiency, making them ideal for high-volume applications.

- Various Material Options: The pumps can be made from different materials, such as cast iron, ductile iron, stainless steel, or other alloys, allowing them to handle a range of water conditions, including corrosive or abrasive fluids.

- Flexibility in Installation: The design of the horizontal split case pump makes it suitable for horizontal installations. Its compact and stable footprint makes it adaptable to limited spaces and simplifies foundation requirements.

Technical Specifications

- Flow Rate: Horizontal split case pumps are typically capable of delivering high flow rates, often in the range of 200 to over 10,000 GPM, depending on the specific model and application.

- Pressure Range: They can operate at pressures from moderate to high, usually up to 300-600 psi.

- Efficiency: Efficiency levels are typically high, often between 80-90%, making them cost-effective for long-term use.

- Size Range: They come in various sizes, allowing them to accommodate diverse piping configurations and system demands.

Applications

Horizontal split case pumps are versatile and are widely used in sectors requiring robust and efficient water pumping solutions:

- Municipal Water Supply: Commonly used for municipal water pumping stations, as they efficiently handle large water volumes for city water distribution systems.

- Industrial Processes: Employed in power generation, mining, and other industries where large water flows and reliable performance are essential.

- Agriculture and Irrigation: Ideal for irrigation systems that require high-capacity water pumps for large-scale farming operations.

- HVAC and Fire Protection: Frequently used in HVAC systems for cooling and heating applications and in fire protection systems due to their reliability and ability to maintain steady pressures.

Advantages

- Easy Maintenance: The horizontal split design enables straightforward maintenance without disturbing the piping.

- High Reliability: The balanced design reduces wear, contributing to long-lasting performance.

- Energy Efficiency: High efficiency helps reduce operational costs over time.

- Adaptability: Suitable for various environments, including those with corrosive or abrasive conditions, due to the range of material options available.

Limitations

- Size and Weight: Horizontal split case pumps can be relatively large and heavy, which may limit installation in compact areas.

- Installation Requirements: They require a solid foundation for proper operation, which may necessitate additional construction in some settings.