Description

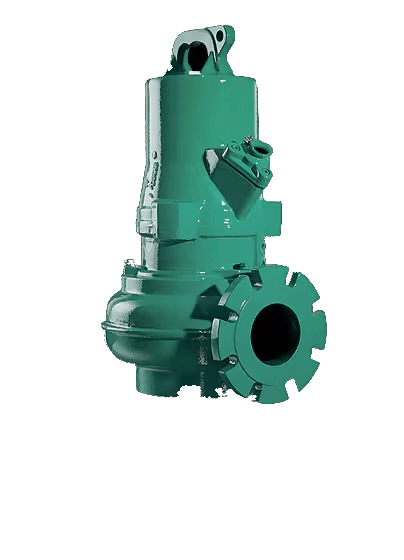

The Wilo-EMU FA is a type of submersible pump manufactured by Wilo, specifically designed for sewage and wastewater pumping applications. The EMU FA series is renowned for its reliability and efficiency in handling heavy-duty wastewater transport, making it suitable for both municipal and industrial environments. These pumps are designed to operate in harsh conditions and are built to handle solid-laden liquids and other challenging media commonly found in wastewater systems.

Key Features of the Wilo-EMU FA Pump:

- Design & Construction:

- Submersible Pump: The Wilo-EMU FA is a submersible pump, which means it is designed to be fully submerged in the fluid it is pumping. This design allows for efficient operation in wet environments, such as sewage systems, drainage pits, and wastewater treatment plants.

- Heavy-duty Construction: The pump is made from corrosion-resistant materials such as cast iron or stainless steel for components like the pump housing and impeller. This ensures long-lasting performance even in aggressive environments where chemicals or abrasive particles may be present.

- Durability: Designed for long operational life, the pump features a robust construction that can withstand the mechanical stresses associated with pumping solids and other difficult media.

- Wide range of impellers: The Wilo-EMU FA series comes with a variety of impeller designs, such as vortex impellers, channel impellers, and multi-channel impellers, to accommodate different types of wastewater and solid-laden liquids.

- Applications:

- Sewage and Wastewater Transport: The Wilo-EMU FA pump is primarily used for pumping sewage, wastewater, and sludge in municipal sewage systems, wastewater treatment plants, and industrial applications.

- Stormwater and Flood Control: It can be used for stormwater drainage and flood control in areas prone to heavy rainfall or flooding.

- Industrial Wastewater: The pump is suitable for pumping industrial wastewater containing suspended solids, grease, and other contaminants often found in manufacturing or chemical processes.

- Lift Stations: It is commonly used in sewage lift stations to lift sewage to a higher elevation for transport through sewer systems.

- Drainage Systems: The pump is ideal for draining construction sites, underground parking garages, or basements where water accumulation occurs.

- Performance & Efficiency:

- High Solids Handling Capability: The Wilo-EMU FA pump is specifically designed to handle liquids with a high concentration of solids, such as sewage, sludge, and industrial wastewater. The pump is capable of handling solid particles up to a certain size, depending on the model and impeller type, without clogging.

- Efficient Operation: The pump is designed for energy-efficient operation, optimizing power consumption while maintaining reliable performance. Its high efficiency minimizes the total cost of ownership over its lifecycle.

- High Flow and Head Capabilities: The Wilo-EMU FA pump can achieve high flow rates and significant pumping heads, making it ideal for both horizontal and vertical pumping applications in large-scale sewage and wastewater systems.

- Motor & Protection:

- The Wilo-EMU FA is powered by a submersible motor, which is enclosed in a waterproof housing. The motor is designed to operate under the water’s surface, ensuring that it is protected from environmental elements.

- The pump comes with thermal overload protection to prevent damage in the event of overheating. The motor protection ensures the pump operates within safe parameters, reducing the risk of failure.

- Dry-run protection: Some models are equipped with dry-run protection to prevent the pump from operating when there is insufficient fluid, which could damage the pump or motor.

- Integrated cooling: The pump’s motor is typically cooled by the fluid being pumped, which ensures optimal performance and prevents overheating.

- Ease of Installation & Maintenance:

- Submersible Design: The submersible nature of the pump makes it easier to install in underground pits or tanks without requiring complex mechanical connections. It is usually suspended directly into the fluid being pumped.

- Plug-and-play: The Wilo-EMU FA is often designed for easy installation with quick-connect electrical connections. This feature allows for faster setup and reduced installation costs.

- Low Maintenance: The pump requires minimal maintenance, thanks to its durable construction and corrosion-resistant materials. Regular inspection and occasional cleaning of the impeller and housing are usually sufficient to ensure long-term reliability.

- Accessible Parts: The design of the pump allows for easier servicing, and its components are accessible for repairs or part replacements when needed.

- Safety Features:

- Thermal and Overload Protection: The motor includes thermal overload protection to prevent overheating, which helps safeguard the pump against damage due to excessive load or failure of system components.

- Waterproof Seals: The pump features high-quality mechanical seals that ensure the motor remains fully protected from water and other liquids during operation.

- Automatic Restart Function: Some models of the Wilo-EMU FA may include automatic restart features after protection trips, which ensures continuous operation without manual intervention.

- Hygienic Design: The pump is designed to meet high hygienic standards, making it suitable for use in applications where cleanliness is essential, such as in wastewater treatment plants.

- Noise & Vibration Control:

- The Wilo-EMU FA is designed to operate with minimal vibration and noise, making it suitable for installation in environments where such issues are a concern. The design ensures smooth operation, reducing wear and improving the longevity of the pump.

Advantages of the Wilo-EMU FA Pump:

- High efficiency in energy consumption and reliable performance.

- Effective solids handling with various impeller options to suit different wastewater conditions.

- Durable construction for long service life in aggressive sewage and wastewater environments.

- Submersible design for easy installation and operation in confined spaces such as tanks and pits.

- Low maintenance and minimal downtime, reducing operational costs.

- Safety and protection features to ensure safe operation in demanding conditions.

- Versatility in a wide range of applications, from municipal sewage systems to industrial wastewater.

Applications of the Wilo-EMU FA Pump:

- Municipal Sewage Systems: For lifting and transporting sewage in public water treatment and sewage systems.

- Wastewater Treatment Plants: Used for pumping raw or treated wastewater between different stages in the treatment process.

- Industrial Wastewater: In industrial facilities to handle effluents from processes such as food processing, chemicals, and manufacturing.

- Stormwater and Drainage: Ideal for flood control and stormwater drainage, especially in areas susceptible to heavy rainfall.

- Lift Stations: To lift sewage to higher elevations in sewage systems.

Conclusion:

The Wilo-EMU FA pump is a robust and efficient submersible solution designed for handling sewage, wastewater, and other solid-laden liquids in demanding environments. Its energy-efficient operation, versatile impeller options, and durability make it ideal for use in municipal and industrial wastewater treatment plants, sewage lift stations, drainage systems, and more. With easy installation, minimal maintenance, and safety features, the Wilo-EMU FA is a reliable pump that ensures continuous, efficient operation in wastewater applications.